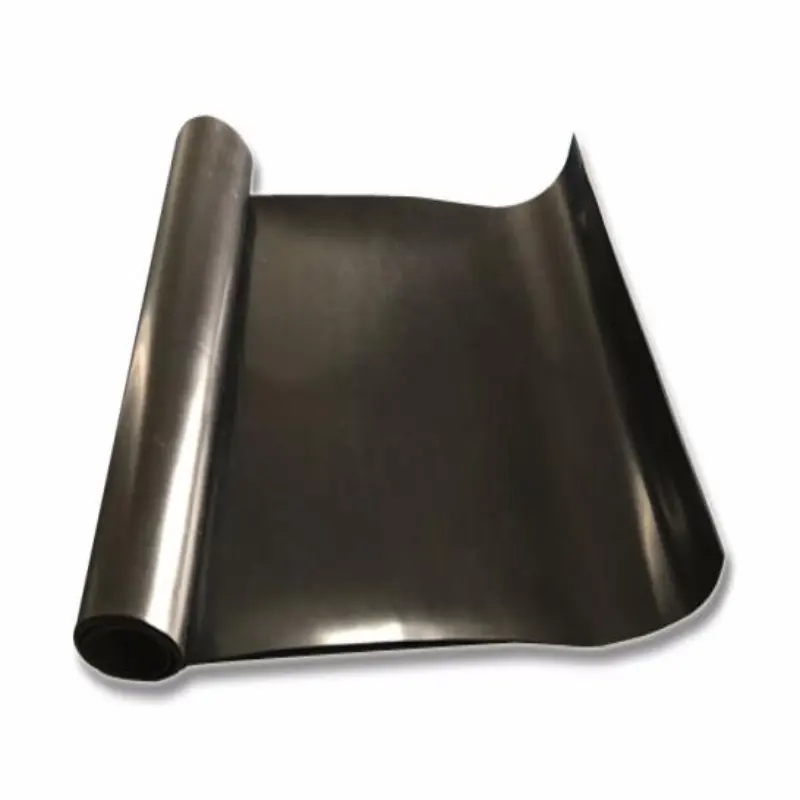

Neoprene rubber, also known as polychloroprene, is a synthetic polymer that has gained popularity in various industries due to its unique composition and outstanding properties. Understanding the science behind neoprene helps illuminate why it is an ideal material for applications ranging from wetsuits to automotive parts.

Chemical Structure of Neoprene

Neoprene is formed through the polymerization of chloroprene, a monomer that is derived from petroleum. The basic chemical structure of neoprene consists of long chains of repeating units of chloroprene. This polymerization process can be accomplished through different methods, including emulsion and solution polymerization, which influence the molecular weight and the properties of the final product.

The presence of chlorine atoms in the polymer chain is a key factor that differentiates neoprene from other types of rubber. These chlorine atoms impart distinct characteristics, enhancing the material’s stability and performance under various environmental conditions. The chemical structure also allows for a cross-linking process during manufacturing, further improving its mechanical properties.

Unique Properties of Neoprene

1. Flexibility

One of the most remarkable properties of neoprene is its flexibility. The polymer chains are able to move and stretch without breaking, allowing neoprene to maintain its shape even under tension. This flexibility is crucial in applications such as wetsuits, where the material needs to conform to the body while providing comfort and ease of movement.

2. Durability

Neoprene is known for its exceptional durability, making it resistant to wear and tear over time. The cross-linking of polymer chains enhances its tensile strength, enabling neoprene to withstand significant stress and strain. This property is particularly valuable in industrial applications, where materials are subjected to harsh conditions and mechanical forces.

3. Chemical Resistance

Neoprene exhibits excellent resistance to a wide range of chemicals, including oils, fuels, and solvents. This resistance is largely due to the polar nature of the chlorine atoms in the polymer, which helps repel various corrosive substances. As a result, neoprene is commonly used in gaskets, seals, and protective gear in environments where chemical exposure is a concern.

4. Weather Resistance

Neoprene’s chemical structure also contributes to its weather resistance. It can withstand UV radiation, ozone, and extreme temperatures without significant degradation. This makes it an ideal material for outdoor applications, such as roofing membranes and protective clothing, where exposure to the elements is inevitable.

5. Thermal Insulation

Neoprene has inherent thermal insulating properties, making it suitable for applications requiring temperature control. Its closed-cell structure provides excellent insulation against heat and cold, which is beneficial in industries like refrigeration and construction.

Applications of Neoprene

Given its unique properties, neoprene is used in a diverse range of applications:

- Wetsuits and Diving Gear: The flexibility and thermal insulation properties of neoprene make it the material of choice for wetsuits, ensuring warmth and comfort in cold water.

- Automotive Components: Neoprene is used for seals, gaskets, and hoses in vehicles due to its durability and chemical resistance, which ensure long-lasting performance.

- Industrial Products: In manufacturing settings, neoprene is used in conveyor belts, shock absorbers, and various sealing solutions due to its strength and resilience.

- Consumer Goods: Neoprene is found in everyday items like laptop sleeves, phone cases, and sports equipment, where protection and cushioning are needed.

- Medical Applications: Its biocompatibility and resistance to chemicals make neoprene suitable for various medical devices and protective gear.

Conclusion

The science behind neoprene rubber reveals a material that combines flexibility, durability, and resistance to chemicals, making it an invaluable asset across various industries. Its unique chemical structure not only enhances its performance but also expands its range of applications. Whether in the ocean, on the road, or in the workplace, neoprene continues to be a versatile and reliable choice for engineers, manufacturers, and consumers alike.